Due to overwhelming response, I am backlogged 25 days on both types of Spall Guards. I will not be accepting new orders until August 17th. If you would like to be placed on the waiting list, please contact me with your information. Thanks for your patience!

Archive for July, 2014

With the recent roll-out by Midwest Armor of their FM4 and FM3 plates (currently the lightest level IV and III rated stand-alone plates respectively), it was hard to contemplate what they could do to top it.

By releasing the FM-STX (“Force Multiplier, Special Threat”) they may have done that. The STX plate fills a niche for a light, THIN rifle plate that won’t break the bank. While the FM3 is still the lightest level III plate out there (~2.2 lb.), it is relatively thick (a hair over 1″) and does not address the M855 threat. The STX does not carry an NIJ level III rating, as it is tested specifically against M193, M855, and 7.62X39 steel core (hence the “Special Threats” designation).

The STX, at just over .55″ thick, and weighing in at 5 lb. in medium ESAPI profile (4.8 lb. in 10X12 shooters cut!), comes in thinner than either the FM3 and the FM4, providing the thinnest profile of the 3 (with the FM4 being .90″ thick). Consisting of a thin monolithic ceramic strike face sitting atop a backing package of advanced, proprietary UHMWPE rigid laminate, it pushes the limits of hard armor technology.

It also compares very well to the SIGMA III+ (review forthcoming), as it is triple curve (compared to the SIGMA III+ single curve), .55″ thick compared to the SIGMA III+ 1.25″ and only about $50 more per plate @ $499. If M80 ball is not a concern, and you need the thinnest non-steel plate to stop common-threat rifle rounds, the STX is the correct choice.

Add to this that Midwest is not satisfied with a single plate profile- the STX is available in all four ESAPI-profile sizes (small, medium, large, X-Large) as well as small and medium shooters cut, and small and medium full cut (rectangle). Options are nice to have.

The price point does place it in the midrange, with the standard MASS III running $399 and the Guardian IV triple curve at $150. But each plate should be considered for the intended end-use. If you are looking for a thin, light ceramic plate that will stop M193, M855, 7.62X39 steel core and all lesser threats (which accounts for a large percentage of typical threats) for PSD work, the STX is the best choice.

Armor is not a one-size fits all proposition, and by increasing the available choices, Midwest continues to lead the industry. Check out the FM-STX plate here:

http://www.midwestarmor.com/body-armor/venture-fm-stx

(Disclosure: As usual, I have not received any financial inducements, discounts, or remuneration from either Midwest Armor, nor Appalachian training. When I do my hands-on review, as usual I will have paid for the plate out of my own pocket).

Or contact Mike at Appalachian training to special order.

Due to overwhelming response, I am now sold out of the Armometer(TM):

https://drmorgear.wordpress.com/project-a/

Should have more in about 30 days. Please contact me to get on the wait list.

Vintage Kevlar Armor; or, Old Armor Better With Age?

Posted: July 13, 2014 in Armor Care, UncategorizedOne of the more interesting tidbits concerning woven Kevlar armor is that it retains its protective qualities exceedingly well over a long period of time. 30+ year old panels still stop the threats they were designed to stop, with boring regularity.

Even more intriguing, is a study showing that older vests may in fact get *BETTER* with age. Wine, cheese, and woven aramid? You can find the abstract here:

Click to access 111390NCJRS.pdf

Some quotations from the article:

“NIJ tests failed to demonstrate any significant differences in 10-year-old armor, regardless of the extent of use or apparent physical condition”

“The warranty exists solely to limit the manufacturer’s liability on the product and is not a reflection of the anticipated service life of the product.

I hear lots of folks say that their department religiously discards vests as soon as the 5 year period is up. While I understand that this is due to departmental liability, the idea that these vests suddenly become worthless is ridiculous. If they are 100% woven kevlar, they are barely broken in, and should easily have another quarter century (or longer) of use left in them. I say longer because I have not been able to get my hands on vests older than about 36 years. Saving a few of these for the 40 year mark, and will report back on the results.

Unfortunately, this extreme longevity only applies to woven aramid vests, and in my experience, the older ones are typically built better than the new. Laminates will experience peeling and edge creep, the newer all-woven vests also see much more edge creep (fraying) that reduces the effective area of protection.

If you have an older vest in good shape, remember there are things you can do to keep it going: keep it out of sun, or exposure to florescent bulbs (which are actually worse in some ways than sunlight), keep it dry, clean, and free of mold or mildew. Wash with clean water (not tap, not distilled) and a mild detergent, let drip dry.

So keep that older vest, and appreciate a well-built vintage armor!

Armor Factionalism: It Continues

Posted: July 13, 2014 in Body Armor The Good The Bad and The Ugly, Opinion, UncategorizedWell, apparently my last post was a little too pointed, as it has already garnered a response. Unfortunately, the response was based on the notion that I am a “supporter” of steel plates over ceramic.

If anyone can show, unequivocally, where I have ever written that steel plates are completely “superior” to ceramic plates, they get a free rock sling.

This is why reading comprehension is so vital, and yet found lacking in most interactions.

Please re-read The Good, The Bad, and The Ugly. No dogs are selected to fight. Just the basic facts about each choice.

I think the problem is that I did not “bash” steel enough compared to ceramic. I will not do so. I make the assumption that all my readers wear big-boy pants, and when I say that steel is HEAVY for type, and experiences FRONT FACE SPALL, they are intelligent enough to weigh these drawbacks versus the advantages. I am not interested in impugning their intellect, or questioning their “seriousness.”

Furthermore, steel is out there. People are using it and will continue to use it. Arguing against something that has such major market penetration is tantamount to arguing against certain computer operating systems, even though we know they have flaws. Instead of lambasting people for their choices, I choose to do something to make that choice safer, just as you can improve your experience with the aforementioned OS with some simple, minor changes. When steel ceases to be used for personal protective gear, so be it.

Finally, it is amusing to me that the response came so quickly- I was not directing it at anyone in particular, certainly not at the guy that responded (inadvertent recon by fire?), but it made my point very clearly. Making a fully informed choice is not purchasing a stake in a fertilizer concern.

The internets are full of pi**ing matches. I am not going to engage in any here.

Let me reiterate, in case the above was too verbose:

Steel= GOOD!

Ceramic= GOOD!

UHMWPE= GOOD!

They will all stop centerfire rifle rounds. They all cost varying amounts of money. They all have varying material properties. They are not all the same. Pick one, or two, or all. Use them. Train with them.

Providing objective evaluations on these different material options does not place me into any “faction.” Providing enhancements to any or all of them does not place me into any “faction.” Except perhaps the “faction” that wants to make any and all armor better and safer.

As Musashi said, know your tools, their strengths and weaknesses. If you do, you will use anything to the fullest extent.

Armor Factionalism: What’s the Point?

Posted: July 11, 2014 in Body Armor The Good The Bad and The Ugly, Opinion, UncategorizedTags: armor factionalism, ceramic rifle plates, opinion, steel rifle plates

It seems that over the past few years there is a growing factionalism and hardening of opinions within the shooting/gear community, and more specifically, regarding choices of armor.

Lately, there have been several very strong pieces written about the complete unsuitability of steel rifle plates, and that ceramic is the *only* viable choice for those who are “serious” about protecting themselves.

While I appreciate an impassioned, well-written argument as much as the next guy, I think that such rigid positions do a disservice to those seeking an honest comprehension of the various self-protection options.

The current “hot topic” of debate seems to be steel vs. ceramic, with proponents of the latter insisting that steel rifle plates have no place whatsoever in the self-protection arena. Ceramic, they argue, is far superior in every way, and steel is nothing but heavy, dangerous, useless dead weight.

One of the primary reasons I started this site was to provide balanced, reasoned, and honest evaluations of various materials and armors that are out there. While it is true that steel has known issues and challenges, ceramic is not perfect, and downplaying these considerations (COST and fragility being the two biggest), do not make them go away. While it is true that there are VERY affordable ceramic plates (the Midwest Guardian IV being at the very top of the list), and also true that ceramic plates are not porcelain dolls, to ignore the fact that EVERY armor (throughout history) is a compromise of many different factors is to ignore reality.

Most people purchase steel plates because they are the most affordable option. They are also hands down the most durable, and if someone has honestly evaluated their needs, and found that they don’t want to worry about their logistics tail (replacing a broken ceramic plate) and would rather allocate the difference in cost to other areas (training/ammo/etc.), then deriding them for their “inferior” choice is not going to alter their decision. It is true that steel plates are heavy for type, and do have issues with front face splash (albeit less of an issue with proper spall-mitigation technologies). But for someone that wants an inexpensive, demonstrably effective way of keeping centerfire rifle rounds out of their vitals, without breaking the bank, steel works.

I advocate selecting the correct tool for the job, and will say right now that not everyone NEEDS a sub-4.5lb. level IV ceramic plate for their particular task. While it is a “nice to have,” most cannot justify the commensurate high cost associated with the “best” armor.

In conclusion, I recommend folks re-read the “Good, Bad, Ugly” posts again. Each of the three major plate types has pros and cons- there is no BEST option for all people or all roles. Know your needs, and know the options. Strong opinions are good, but they should be tempered by the realization that not everyone needs/wants the same thing.

There are some things that just need to exist. UHMWPE (Spectra and Dyneema) armor, though light and exceptionally strong, has an Achilles heel- it will turn back into milk jug plastic if certain temperature thresholds are exceeded.

This applies to both soft and hard armor containing Spectra and Dyneema, and there are currently no test standards that are willing to address this glaring weakness as mentioned here:

UHMWPE, Test Protocols and Temperatures: What You Should Know

Since many end-users do not have a choice in their issued armor, I realized a simple, effective solution was needed. I had a custom thermal sensor created, which would irreversibly change color if certain temperatures were reached. This would let the end user know that the armor had been exposed to unsafe temperatures, preventing them from using potentially compromised armor.

The D-Rmor Gear Armometer(TM) is a dashboard for your hard or soft armor, and is overbuilt to stand up to the lifetime of wear associated with duty gear. With a foundation of waterproof paper, it has information sections to record relevant data about the specific panel the Armometer(TM) will be attached to. This is then sealed with an included laminate finish-flap to completely render the unit sweat and moisture proof. It is designed to stay with the panel, plate, or helmet for its entire service life. It answers the number one question with UHMWPE armor: is it still viable?

Pricing is $12 for the first Armometer(TM), with additional units being $8, no matter how many you buy. Shipping is included in the price, anywhere in CONUS.

Get yours today, and increase your peace of mind.

Shoot Test: Version 4.2.3 Spall Guard and Maingun Patriot Plate

Posted: July 10, 2014 in Armor Testing, Spall, Spall GuardsAs many of my readers know by now, steel plates offer tremendous advantages (low cost, extreme durability/multiple hits, thin profile), but do suffer from issues with front-face spall (fragmentation caused by defeated rounds) and weight. Most solutions that attempt to address this issue exacerbate the weight, and negate the advantage of a thin profile.

D-Rmor Gear spall guards address the issue while remaining lightweight and keeping the thin steel plate profile, while stopping 95-98% of all front face spall. The newest version exhibits improved extreme angle spall capture, as shown by the test below.

The plate used was the excellent Maingun Surplus Patriot plate, in flat profile. The plate was placed at a 12 degree angle (to focus the splash pattern more strongly toward the upper edge where the neck/throat would be). This is closer to a worst-case scenario shot, since the residual velocity of the spall is higher.

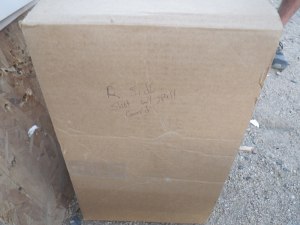

The test rounds were M855, 20″ barrel, 3000 fps @ 10 FEET. The witness method was a cardboard box. The shoot consisted of two shots, the first with the D-Rmor Gear Version 4.2.3 spall guard installed, the second with the bare plate. The pictures below show the witness box after the first and second shots for direct comparison purposes.

Interior of witness material, first shot, spall guard installed. Note near complete absence of *any* spall whatsoever.

As you can see, the shot with the guard resulted in nearly total capture of all spall, INCLUDING THE STEEL CORE. The core was captured by the spall arrest material, as can be seen in the upper left angle of the plate. M855 is particularly nasty as a threat, because the spall is lead, copper, AND the steel core, which tends to remain in one piece. In a plate carrier, none of the spall would have had sufficient energy to escape.

Some things to consider when viewing this test: front face spall will punch through wooden target stands, both sides of steel aerosol cans from several feet away, and deeply indent angle iron. The spall guard caught the overwhelming majority of this extremely energetic frag while being UNDER 5 oz. weight and containing NO metal itself.

Top edge, second shot, BARE PLATE NO GUARD INSTALLED- note large amount of spall cutting in chin and throat area. Compare to first pic with guard installed.

Right edge of witness material, second shot, BARE PLATE NO GUARD INSTALLED, showing massive spall cutting.

Left side of witness material, second shot, BARE PLATE NO GUARD INSTALLED, showing massive spall cutting.

Another picture of top edge, second shot, BARE PLATE NO GUARD INSTALLED, showing high energy of spall fragmentation leaving the box and spall cutting.

Right side of witness material, NO GUARD INSTALLED, again note sheer volume of fragmentation and spall cutting without the guard to catch it.

The second shot (bare plate/no guard), in contrast, shows massive spall/fragmentation. So dense is the pattern that it often looks like a saw or cutting tool was used on the cardboard. The majority exits along the edge of the plate, and as can be seen, would have impacted the neck/throat and arms.

Moral of the story? Spall guards are essential when running steel plates.

The Maingun plates are quite impressive. The two M855 rounds impacted almost in the same spot, with only a slight indentation and barely detectable bump on the backside. I will be performing a torture test on this same plate to see how many M855 rounds it can soak up before penetration or cracking, and I have a feeling it will be in the hundreds.

Overall, the new version 4.3.2 guard performed exactly as designed, capturing and mitigating the cloud of high velocity metal that is produced when a round hits steel. Check them out here:

https://drmorgear.wordpress.com/products/spall-guards/

The new style curved Patriot plates can be found here:

http://www.maingun.biz/Body_Armor_Steel_Patriot_Plate_p/patplatepair10x12twocurve.htm

Stay tuned for further shoot tests!